08 Oct What is the difference between sanitization and sterilization?

What is the difference between sanitization and sterilization?

The Coronavirus emergency and the need to restrict the contagion due to Covid-19 virus has fostered the use of terms such as cleaning, disinfection, sanitation and so on. These terms have often been used randomly, not considering their real differences. Knowing their exact meaning protects you from many risks.

It is essential for a reliable professional cleaner to understand the differences between these terms and to know what particular sanitation protocol is expected or intended to be achieved.

Cleaning and sanitizing pubs, machines, equipment, furnishings and work tools is a key factor in the management of highly frequented areas, in order to avoid or contain the transmission of infectious diseases, mostly in the current epidemiological emergency conditions due to the Sars-Cov-2 virus.

Let’s be very clear about the definitions of cleaning, sanitation, disinfection and sterilization.

What is cleaning?

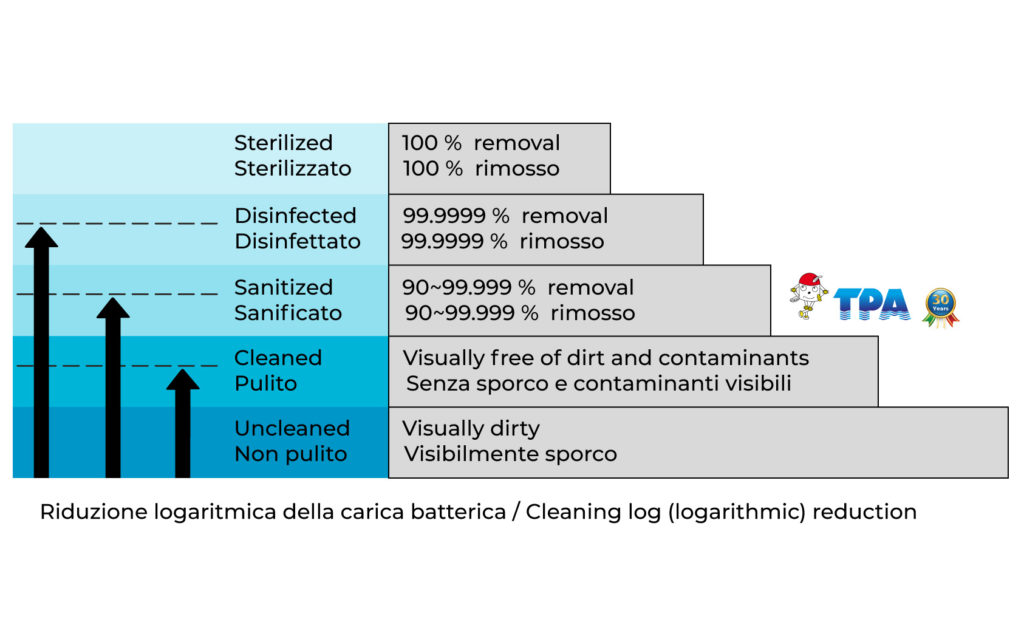

Cleaning removes germs, dirt and impurities from surfaces or objects. Cleaning works by using soap (or detergent) and water to physically remove germs from surfaces. This process doesn’t necessarily kill germs, but removing them decreases their number and the risk of spreading the infection.

The difference between cleaning and sanitizing

Sanitation reduces the number of germs on surfaces or objects to a safe level, as set by public health standards. This term indicates the set of activities aimed at making an environment healthy, that is, healthy and suitable for its intended use. It can be assimilated to the broader concept of “hygiene” where germs are physically removed from surfaces and objects. However, it can also mean a significant reduction in microbial load in order to reduce the risk of spreading the infection. Sanitation is generally a slightly more delicate process than disinfection: in this process, pathogens are removed and inactivated to a safe level, often with a reduction from 1 to 5 log (90-99.999%).

Disinfection with the use of chemicals

Disinfection refers to the use of chemicals to kill germs on surfaces or objects. Dirty surfaces are not cleaned and germs aren’t removed during this process, but germs are killed on a surface after cleaning. This can further reduce the risk of spreading the infection by removing or inactivating unwanted microorganisms up to a 6-log reduction (99-99.9999%).

Sterilization and aseptic technique

In surgery specific rules must be followed. These rules are called aseptic techniques. Aseptic technique is the foundation on which practically every surgical activity rests. These rules are not simple guidelines, but real laws inside the operating room and violating them means subjecting patients to the danger of disease or infection. In addition to the rules of asepsis, practices are followed to ensure that the operating room is as clean and non-pathogenic as possible. In this case, sterilization is an indispensable process, which destroys and eliminates all forms of microbial life and is carried out in the health sector with physical or chemical methods. During this process 100% of the microorganisms are removed and inactivated.

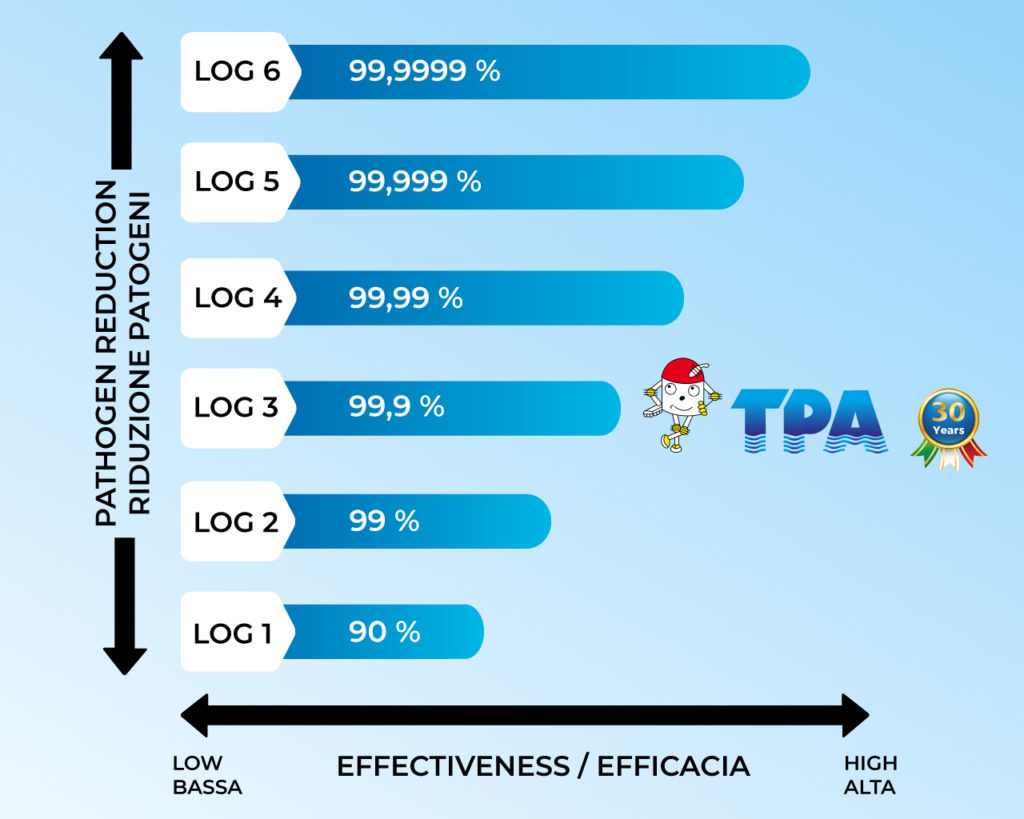

Logarithmic reduction of bacterial load

The number of logs is equal to the number of 9 which express the reduction coefficient exercised against the infectious pressure. Consequently, we can derive the following inactivation percentages:

- 1 Log reduction = 90% inactivation

- 2 Log reduction = 99% inactivation

- 3 Log reduction = 99.9% inactivation

- 4 Log reduction = 99.99% inactivation

- 5 Log reduction = 99.999% inactivation

- 6 Log reduction = 99.9999% inactivation

- 7 Log reduction = 99.99999% inactivation

- 8 Log reduction = 99.999999% inactivation

- 9 Log reduction = 99.9999999% inactivation

- 10 Log reduction = 99.99999999% inactivation

Using steam for a proper sanitation

A temperature of 80 °C (176 °F) or higher on the contact surfaces is known to remove most bacteria and inactivate most viruses. With an extended exposure time from a few seconds to 30 minutes (depending on the pathogen), even the temperature of 60 °C (140 °F) is capable of removing or inactivating pathogens. Steam reaches high temperatures and this guarantees complete sanitization and inactivation of viruses and bacteria in the environment with a single treatment.

Furthermore, steam sanitization does not require the use of chemical detergents and is perfect for sanitizing high-traffic areas, because it allows normal work to be resumed immediately after the end of the treatment without health risks. Steam is widely used in the food & beverage sector and in other manufacturing industries for its natural sanitizing effect.

TPA professional steam generators for an effective, safe and ecological sanitation

Sanitation has always been important, but with the current pandemic it has played a decisive role. We are experiencing a health crisis that most of us have never experienced before. Covid-19 has almost paralyzed the country and threatens the health of people around the world. Schools and businesses have been closed, and healthcare professionals are facing an unprecedented shortage of medical supplies as they care for the growing number of Covid-19 patients.

From the current health crisis, we can learn to understand the importance of a regular cleaning and sanitizing routine. Many of the coronavirus cases were contracted and transmitted well before we were aware of doing so. The more cleaning and sanitization there are in the environment in which we live or work, the better we’ll be prepared to avoid creating environments that facilitate the proliferation of viruses.Any environment is subject to such problems, think for example of places such as gyms, schools, hotels, kindergartens, public places: all environments in which there is a concentration and turnover of people. Steam is extremely versatile and can be used in different applications to sanitize several environments.

The strengths of our steam generators equipped with a patented water filter and UV-C germicidal lamp are:

- Efficient cleaning process: Sanitation and quick suction, in a single step

- Low operating costs: No additional detergents or extra cleaning tools needed

- 60% faster: Clean all surfaces with just one machine

- 93% less water use: Incredible cost reduction compared to cleaning with traditional methods

- Consistent cleaning power: Continuous steam thanks to the patented boiler associated with practical refill tanks

- TÜV SÜD, HACCP and NSF certified products: recommended for professional cleaning in food industries, pubs, restaurants, bakeries, pastry shops.

- Hygienically clean: Patented filtering system with UVC germicidal lamp that removes mold, viruses, germs and bacteria up to 99.9% (LogStufe 2.89 ± 0.15)

Increase the efficiency of your business also in sanitation.

Our innovative domestic, professional and industrial steam generators stand out for the optimization of the cleaning processes and for the high filtering efficiency.

The winning formula is very simple: a better cleaning result, in a short time.

Fill out the contact form for more information.